Clutch Kit Component Explorer

Select a component below to learn more about its role in your clutch system.

Clutch Disc

Friction PlateThe heart of the clutch system, transferring torque through friction.

Pressure Plate

Clamping ForceApplies pressure to hold the disc against the flywheel.

Release Bearing

DisengagementEngages the pressure plate to disengage the clutch.

Pilot Bushing

AlignmentKeeps the transmission input shaft centered during operation.

Clutch Fork

ActuationTranslates pedal motion into force on the release bearing.

Hydraulic Cylinder

Hydraulic SystemProvides hydraulic pressure to operate the clutch.

Component Details

Select any component card above to see detailed information about its function and importance.

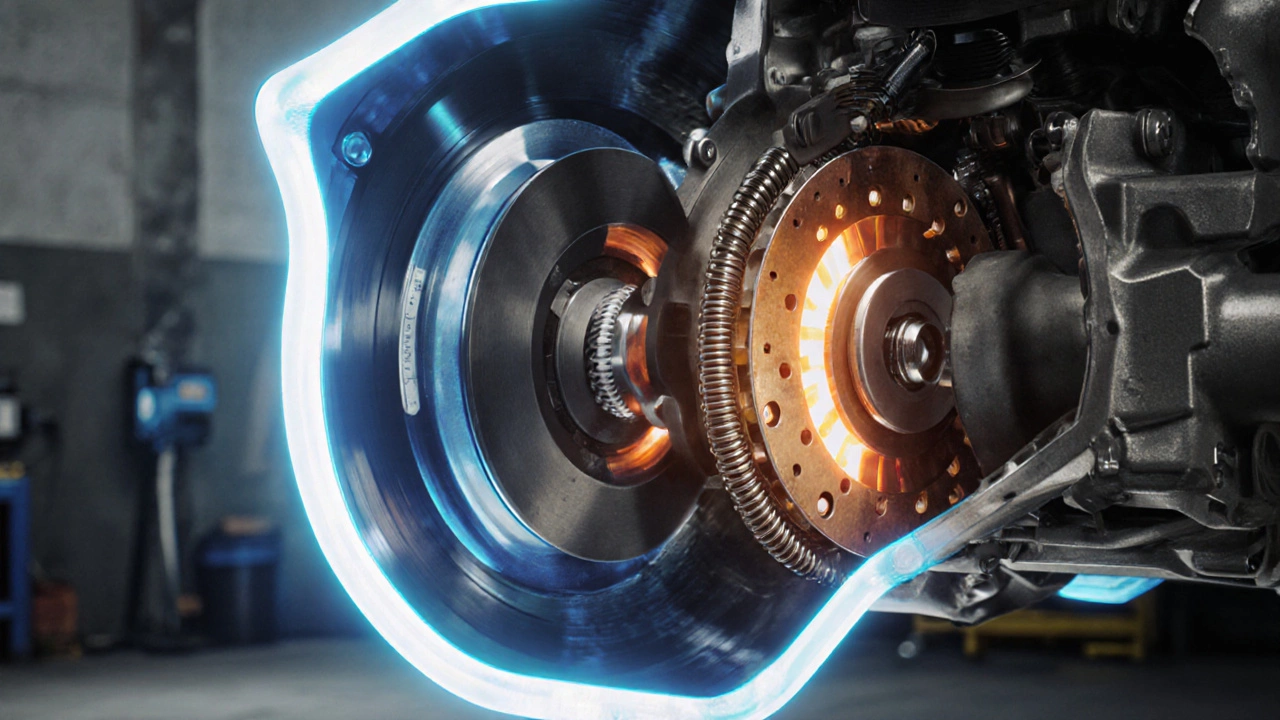

Ever wondered what actually sits between your engine and wheels when you press the pedal? The answer lies in the clutch kit - a compact collection of parts that let you disengage the power flow, shift gears smoothly, and keep the drivetrain alive. Knowing what’s inside helps you pick the right kit, avoid costly mistakes, and spot problems before they snowball.

Quick Summary

- A standard clutch kit includes a clutch disc, pressure plate, release (or throw‑out) bearing, pilot bushing, and often a clutch fork.

- OEM kits match factory specs; aftermarket kits offer price or performance variations.

- Installation usually requires removing the transmission, aligning the kit with the flywheel, and torquing bolts to exact specs.

- Common wear signs: slipping, hard pedal, noise, or vibration.

- Regular inspection and proper break‑in can double the life of your kit.

Core Components of a Clutch Kit

Clutch disc is the heart of the kit. It’s a friction plate sandwiched between the pressure plate and the flywheel. Modern discs use ceramic or organic linings that balance grip and heat resistance. The disc’s diameter, thickness, and spline count must match the transmission input shaft.

Pressure plate applies the clamping force that holds the disc against the flywheel. It contains a set of springs (series or diaphragm) that determine pedal feel. Diaphragm plates give a lighter pedal and are common in newer cars, while series plates are preferred for heavy‑duty trucks.

Release bearing, also called a throw‑out bearing, sits on the input shaft and engages the pressure plate’s release fingers when you press the clutch pedal. A worn bearing creates a growling or squealing noise that rises with engine RPM.

Pilot bushing (or pilot bearing) fits into the end of the flywheel’s hub. It supports the transmission input shaft when the clutch is disengaged, keeping it centered. Failure shows up as a shudder when you shift out of neutral.

Clutch fork translates pedal motion into hydraulic or mechanical force on the release bearing. In hydraulic systems the fork pivots on a pivot point; in cable‑actuated setups it pulls a cable that moves the bearing.

Other optional items often bundled: a new hydraulic master cylinder, fresh clutch fluid, and a set of clutch pedal hardware (bushings, pivots). Including these ensures a complete rebuild without hidden surprises.

How the Parts Work Together

- When the pedal is released, springs in the pressure plate push the disc tightly against the flywheel, transmitting engine torque.

- Pressing the pedal forces the release bearing to pull the pressure plate’s fingers outward, relieving pressure on the disc.

- The disc disengages, allowing the transmission to shift gears without crushing the gear teeth.

- The pilot bushing keeps the input shaft aligned, preventing the gearset from wobbling during a shift.

- After the shift, the pedal returns, springs re‑clamp the disc, and power flow resumes.

This dance happens in milliseconds, but every component must be within tolerance. A cheap disc with a thin friction layer will slip under load, while an undersized release bearing can wear the pressure plate’s fingers.

Choosing the Right Kit: OEM vs. Aftermarket

| Aspect | OEM Kit | Aftermarket Kit |

|---|---|---|

| Fitment | Exact factory match | May require minor modifications |

| Cost | Higher price | Usually 20‑30% cheaper |

| Performance | Balanced for daily use | Specialty options (high‑torque, racing) |

| Warranty | Factory warranty (often 2 years) | Varies by brand, typically 1‑year |

| Availability | Dealer networks | Online retailers, auto parts stores |

For a commuter sedan, an OEM kit offers peace of mind - everything matches the original specs. If you run a light truck or love track days, an aftermarket kit with a higher‑clamp pressure plate or a performance disc can give you the edge.

Step‑by‑Step Installation Overview

Below is a high‑level checklist. Always consult the service manual for torque values and safety warnings.

- Secure the vehicle on jack stands and disconnect the battery.

- Remove the driveshaft or CV axle, then detach the transmission bell housing bolts.

- Support the transmission with a jack, slide it back, and set it aside.

- Inspect the flywheel for cracks or hot‑spot wear. Resurface or replace if needed.

- Press out the old release bearing and pilot bushing using a bearing puller.

- Install the new pilot bushing, then slide the new clutch disc onto the input shaft, ensuring the splines align.

- Place the pressure plate over the disc, line up the bolt holes with the flywheel, and torqued the bolts in a criss‑cross pattern (usually 30‑40Nm for passenger cars).

- Mount the new release bearing, re‑install the clutch fork or hydraulic cylinder, and reconnect any hydraulic lines.

- Re‑align the transmission, bolt the bell housing, reinstall the driveshaft, and refill clutch fluid to the correct level.

- Bleed the hydraulic system, patch the battery, and perform a short road test. Listen for noises and feel for pedal consistency.

Missed a torque step? You risk warping the flywheel or creating uneven clamping, which leads to premature wear.

Maintenance Tips & Common Issues

- Slip on acceleration: Usually a worn disc or weak pressure plate springs. Swap the disc before the springs if you notice heat marks.

- Hard pedal feel: Check the release bearing for binding or a mis‑adjusted hydraulic cylinder.

- Noise when clutch is engaged: May be a dry release bearing or a damaged pressure plate finger.

- Vibration at a certain RPM: Look for a warped flywheel or an unevenly torqued pressure plate.

- Fluid contamination: Replace clutch fluid every 2‑3 years; moisture can cause bearing corrosion.

Regularly inspect the clutch pedal bushings and the hydraulic line for leaks. A quick visual check every 6000miles can save you from a full‑kit replacement.

Frequently Asked Questions

What is the difference between a disc and a cone clutch?

Disc clutches use a flat friction plate and are standard in most passenger cars because they provide smoother engagement and are easier to service. Cone clutches have a tapered friction surface, offering higher torque density but are typically found in motorcycles and race cars.

Can I reuse the flywheel when I replace a clutch kit?

If the flywheel is within thickness tolerances and shows no cracks, hot spots, or glazed surfaces, it can be resurfaced and reused. Many mechanics recommend resurfacing to ensure a flat mating surface for the new disc.

Do hydraulic clutch kits need a different master cylinder?

Usually the original master cylinder works fine if it’s in good condition. However, some high‑performance kits recommend a larger‑bore cylinder to improve pedal feel and reduce pedal travel.

How long should I let a new clutch kit “break‑in”?

Most manufacturers suggest a gentle break‑in period of about 500 miles: avoid aggressive launches, hold the revs under 3,000rpm, and shift smoothly. This lets the friction material seat properly.

Is a single‑disk clutch kit enough for a light‑duty truck?

For most light‑duty trucks, a single‑disk kit with a high‑clamp pressure plate handles the torque. If you routinely tow near the vehicle’s maximum rating, consider a dual‑disk or a heavy‑duty kit with reinforced springs.