Clutch Lifespan Calculator

Recommended Maintenance

Regularly check hydraulic fluid and avoid riding the clutch pedal.

Wondering how long a Clutch is the device that links the engine to the transmission, allowing you to change gears and stop the car without killing the engine will keep working before it needs a swap? The answer isn’t a single number - it hinges on how you drive, what you drive, and how you look after it. Below you’ll find the key factors that shape a clutch’s service life, realistic mileage ranges, warning signs, and practical steps to stretch that clutch lifespan as far as possible.

What Determines a Clutch’s Service Life?

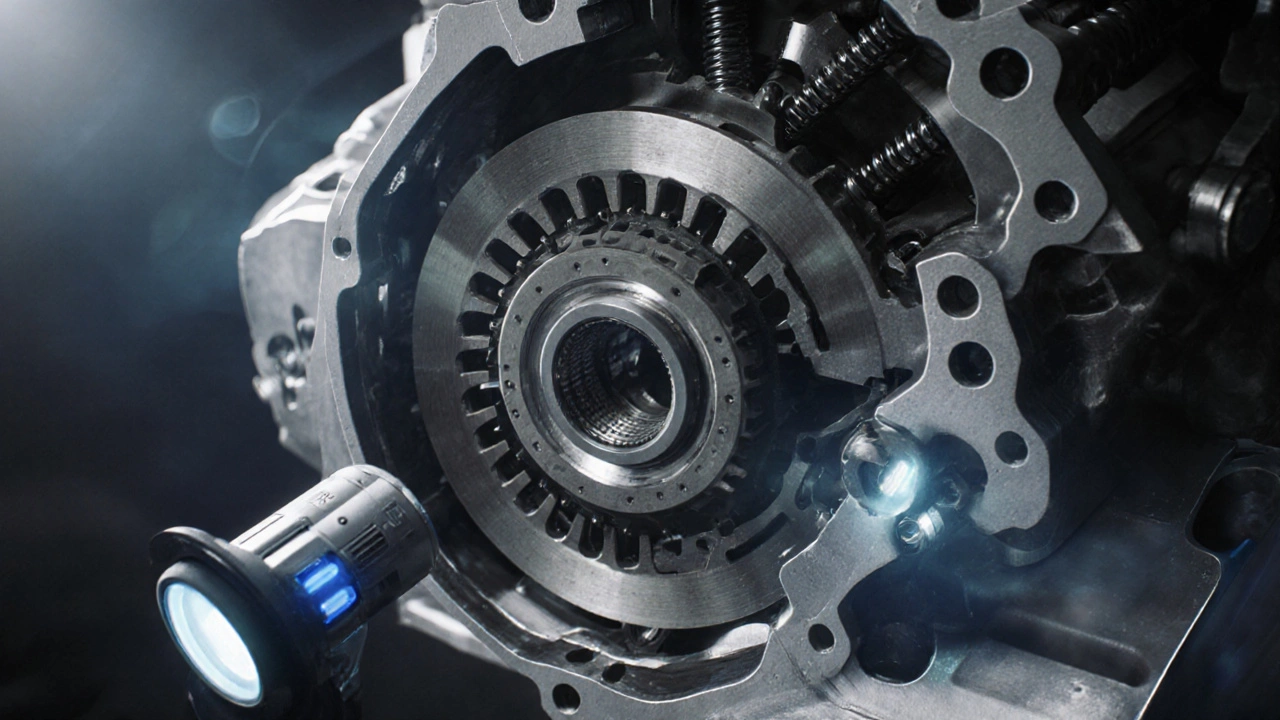

Even though a clutch looks simple - a friction disc, pressure plate, release bearing, and a few springs - it’s subject to a lot of stress. The following entities all play a role:

- Driving Style: Aggressive launches, frequent hill starts, and riding the clutch pedal all add heat and wear.

- Vehicle Type: Heavy trucks and performance cars use larger, higher‑torque clutches that tend to wear faster.

- Mileage / Years: High mileage naturally means more wear cycles, but age‑related material fatigue can matter too.

- Engine Torque: A high‑torque engine pushes more force through the clutch disc each shift.

- Clutch Material: Organic, ceramic, and carbon‑based discs each have distinct durability profiles.

- Hydraulic vs. Cable System: Hydraulic setups often provide smoother actuation and less pedal wear.

Understanding how these pieces interact helps you predict when your clutch might give out.

Typical Lifespan Ranges by Vehicle Category

| Vehicle Type | Typical Lifespan (miles) | Typical Lifespan (years) |

|---|---|---|

| Compact cars (e.g., Ford Fiesta, VW Polo) | 70,000‑100,000 | 5‑8 |

| Mid‑size sedans (e.g., Toyota Camry, Honda Accord) | 80,000‑120,000 | 6‑9 |

| Performance coupes (e.g., Subaru WRX, BMW M3) | 40,000‑70,000 | 3‑5 |

| Heavy‑duty trucks (e.g., Ford F‑150, Chevrolet Silverado) | 60,000‑90,000 | 5‑7 |

| Diesel commercial vans (e.g., Mercedes Sprinter) | 100,000‑150,000 | 8‑12 |

These numbers are averages from real‑world service data collected by UK garage chains and the Society of Motor Manufacturers and Traders (SMMT) in 2024. Your actual experience may be higher or lower depending on the factors above.

Warning Signs That Your Clutch Is Nearing End‑of‑Life

Spotting trouble early can save you from a roadside stall. Keep an eye out for these symptoms:

- Slipping: Engine revs rise but the car stalls or accelerates sluggishly - the clutch isn’t fully engaging.

- Hard Shifts: A grinding or “notchy” feel when moving between gears, especially into first or reverse.

- Spongy Pedal: Excessive travel before the bite point, often due to a worn release bearing or air in the hydraulic line.

- Clunking Noise: A dull thud when you press the clutch pedal, indicating possible wear on the pressure plate or flywheel.

- Vibrations: Shuddering at the bite point, often caused by uneven wear on the friction disc.

If you notice any of these, book a diagnostic sooner rather than later. Ignoring them can lead to total clutch failure, which usually ends in a costly tow.

Maintenance Tips to Prolong Your Clutch

Unlike oil changes, clutch care is mostly about how you treat it. Here are proven habits that help you get the most out of the component:

- Don’t ride the pedal. Keep your foot off the clutch unless you’re actively shifting.

- Shift smoothly. Match engine speed to gear speed - double‑clutching isn’t needed on modern synchro gearboxes, but quick, firm shifts reduce wear.

- Avoid aggressive launches. Gradual throttle application reduces heat buildup on the friction disc.

- Use hill‑assist tools. If your car has a hill‑hold assist, let it do the work rather than holding the clutch on a steep incline.

- Check hydraulic fluid. For hydraulic clutches, ensure the fluid is clean and at the correct level; contamination accelerates bearing wear.

- Inspect the flywheel. When replacing a clutch, have the flywheel resurfaced if it shows hot spots or scoring - a smooth surface improves clutch bite.

Following these habits can add 20‑30% more mileage before a replacement becomes necessary.

Replacing a Clutch: What to Expect

A clutch rebuild typically involves removing the transmission, swapping the friction disc, pressure plate, release bearing, and sometimes the Flywheel. Labor costs in the UK average £400‑£600 for a standard manual, with parts ranging from £150‑£400 depending on OEM vs aftermarket. Performance upgrades (e.g., upgraded pressure plates or ceramic discs) can push the total to £1,000‑£1,500.

Key things to discuss with your mechanic:

- Will the Clutch Pedal need adjustment after the job?

- Is the Transmission Fluid being refreshed at the same time?

- Should the Pressure Plate be upgraded for my driving style?

Even if you plan to replace the clutch later, a proper installation now sets a solid foundation for future performance.

Quick Reference: Clutch Lifespan Checklist

- Know your vehicle’s typical mileage range (see table above).

- Monitor driving habits - aggressive use reduces lifespan.

- Watch for slipping, hard shifts, spongy pedal, noises, or vibrations.

- Perform regular hydraulic fluid checks and change if dirty.

- Schedule a clutch inspection every 30,000‑40,000 miles if you drive hard.

Keep this list on your dash or in your garage notebook; it’s a handy reminder to catch problems early.

Frequently Asked Questions

What is the average mileage before a clutch needs replacement?

Most everyday cars see a clutch last between 70,000 and 120,000 miles. Performance or heavy‑duty vehicles often fall on the lower end, while diesel vans can exceed 150,000 miles with gentle driving.

Does the type of clutch material affect its lifespan?

Yes. Organic (sintered) discs are common and affordable but wear faster under high torque. Ceramic and carbon‑fiber discs handle heat better and can last 30‑50% longer, but they’re pricier and sometimes harsher on the flywheel.

Can I replace a clutch myself?

If you have a good set of tools, a lift, and a service manual for your model, a DIY swap is doable. However, you’ll need to remove the transmission, which is heavy and requires a torque‑wrench for correct bolt specs. Many hobbyists tackle it, but first‑time mechanics often benefit from a professional’s assistance.

How often should I service the hydraulic clutch system?

Check the fluid level at every oil change (about every 7,500 miles). Replace hydraulic fluid every 40,000‑50,000 miles or if it appears dark and contaminated.

Is a slipping clutch dangerous?

A slipping clutch reduces acceleration and can cause overheating, which may lead to sudden failure. While not an immediate safety risk, it can leave you stranded, especially on hills or highways.