Clutch Replacement Decision Guide

Vehicle Information

Symptoms

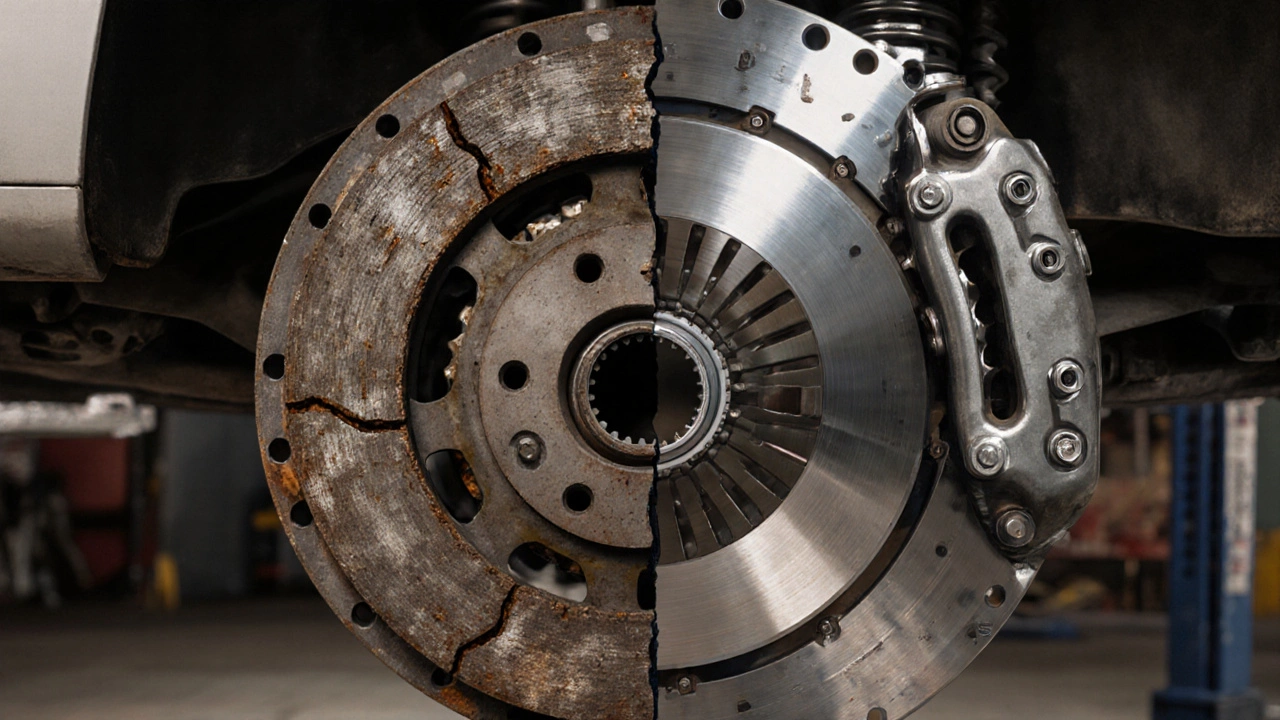

Clutch is a mechanical device that connects engine power to the transmission, allowing you to change gears smoothly. When the clutch finally goes bad, most DIYers wonder whether swapping out the clutch alone will solve the problem. The truth is, a failing clutch usually drags other parts into the same misery. Replacing the right supporting components at the same time saves you time, money, and the dreaded "clutch‑again" visit to the garage.

Quick takeaways

- Replace the flywheel, pressure plate, clutch disc, release (throw‑out) bearing, and pilot bearing whenever you overhaul the clutch.

- Inspect the hydraulic system (master & slave cylinders) and clutch fluid; flush if dirty or contaminated.

- Typical lifespans: clutch disc≈60‑100kkm, flywheel≈150‑200kkm, release bearing≈80‑120kkm.

- Cost ranges (UK market, 2025): clutch kit£300‑£650, flywheel resurfacing£80‑£150, release bearing£30‑£70.

- Use a clutch alignment tool and a torque‑controlled impact driver to avoid common installation errors.

Key components you should replace

Flywheel

Flywheel is a heavy steel disc attached to the crankshaft that stores rotational energy and provides a friction surface for the clutch. Even if it looks flawless, years of heat cycling create micro‑cracks that can cause hot‑spot warping. A warped flywheel leads to clutch chatter and premature wear. The safest route is to replace it outright or have it resurfaced to within 0.02mm flatness.

Pressure plate

Pressure plate is a spring‑loaded component that clamps the clutch disc to the flywheel when the clutch pedal is released. Springs lose tension over time, especially in wet or dusty climates like Manchester. A fresh pressure plate ensures even pressure distribution and prevents the disc from slipping.

Clutch disc

Clutch disc is a friction‑filled plate that transmits engine torque to the transmission input shaft. The disc is the obvious wear item. Look for glazing, uneven wear, or burnt spots. Modern organic and ceramic compounds can last 80‑120kkm, but a new disc is cheap insurance when you already have the transmission out.

Release (throw‑out) bearing

Release bearing is a rotating bearing that disengages the clutch when you press the pedal. A failing bearing produces a growling noise that rises with engine RPM. Since it sits directly in the clutch housing, replacement is almost mandatory after a clutch removal.

Pilot bearing (or bushing)

Pilot bearing is a small bearing that supports the end of the transmission input shaft, keeping it centered on the flywheel. Worn pilots cause gear grinding when shifting into first or reverse. Replacement costs are low (≈£15‑£30) and the part is easy to swap.

Hydraulic clutch system

The clutch in most modern cars is actuated hydraulically. The master cylinder pushes fluid to the slave cylinder, which moves the release bearing. Over time, seals leak, and brake‑type fluid absorbs moisture. Flush the system and replace both cylinders if you notice a soft or spongy pedal feel.

Clutch fluid

Use DOT4 brake fluid (or manufacturer‑specified fluid) and change it every 2‑3years. Contaminated fluid can corrode internal seals, leading to premature failure of the master or slave cylinder.

Comparison of the most common replace‑able parts

| Component | Typical lifespan (km) | UK 2025 cost range | Installation difficulty* |

|---|---|---|---|

| Flywheel (new) | 150‑200k | £250‑£450 | High - requires torque‑controlled impact |

| Flywheel (resurface) | 150‑200k (if no cracks) | £80‑£150 | Medium - needs specialist machine |

| Pressure plate | 120‑180k | £70‑£130 | Medium - bolt pattern alignment |

| Clutch disc | 60‑100k | £80‑£200 | Medium‑high - disc position critical |

| Release bearing | 80‑120k | £30‑£70 | Low - simple press‑out |

| Pilot bearing | 100‑150k | £15‑£30 | Low - pull‑out and press‑in |

| Master cylinder | 120‑180k (if sealed) | £60‑£120 | Medium - bleed system after install |

| Slave cylinder | 120‑180k | £40‑£90 | Medium - similar to master |

*Difficulty rating based on typical DIY experience without specialised lifts.

Inspection checklist before you strip the gearbox

- Listen for a whine or growl that changes with engine speed - signs of a failing release bearing.

- Check clutch pedal free play; less than 10mm usually indicates hydraulic wear.

- Look through the clutch housing for oil leaks; oil on the disc means a rear‑main seal breach.

- Rotate the flywheel by hand; any wobble greater than 0.02mm suggests resurfacing or replacement.

- Inspect the pressure plate springs for fatigue - broken or flattened springs are easy to spot.

- Measure the pilot bearing shaft run‑out with a dial indicator; >0.1mm shows wear.

Installation tips and common mistakes to avoid

- Use a clutch alignment tool. Skipping it leads to uneven disc wear and noisy disengagement.

- Torque the flywheel bolts to the manufacturer’s spec (often 85‑95Nm) in a criss‑cross pattern.

- Apply a thin layer of high‑temperature anti‑seize on the flywheel bolt threads - avoid getting any on the friction surfaces.

- Never reuse the old release bearing; even a tiny crack will destroy the new clutch.

- Bleed the hydraulic system thoroughly. Air bubbles cause a soft pedal that mimics clutch wear.

- Break in the new clutch by avoiding high‑rev launches for the first 15‑20minutes of driving.

When to replace each part - decision guide

If your car has over 80000km on the clutch and you’re planning a rebuild, follow this rule of thumb:

- Flywheel - replace if you detect heat spots, cracking, or if it’s a cast‑iron type older than 100000km.

- Pressure plate - swap if springs show any loss of tension or the plate is warped.

- Clutch disc - always replace; a used disc rarely lasts another full service interval.

- Release bearing - replace with every clutch job; cost is negligible versus the risk of future failure.

- Pilot bearing - replace if you hear a grinding noise in first or reverse gear.

- Hydraulic cylinders - replace if you notice fluid leaks or a spongy pedal after a bleed.

- Clutch fluid - flush every 2‑3years regardless of mileage.

Related systems to check while you’re in there

Because the clutch sits between the engine and transmission, a few other parts deserve a glance:

- Engine mounts - worn mounts amplify vibration, making clutch wear appear faster.

- Transmission input shaft - inspect for keyway wear; a damaged key can ruin a new clutch.

- Gearbox oil - replace with fresh oil of the correct viscosity (often 75W‑90 for manual gearboxes).

- Clutch pedal linkage - ensure no play or corrosion in the pivot points.

Next steps after the rebuild

Once everything’s bolted back, take the car for a short test drive. Start in first gear, let the engine rev a bit, then press the clutch fully and shift to second. You should feel a solid bite, no judder, and the pedal should return quickly. If you notice any chatter, double‑check the flywheel flatness and pressure plate torque.

Frequently Asked Questions

Do I really need a new flywheel when I replace the clutch?

In most cases, yes. Even a flywheel that looks fine can have hidden cracks or surface hardening from heat. A warped flywheel will cause the clutch disc to chatter, shortening its life dramatically. Resurfacing works if the disc is still within thickness limits and free of cracks; otherwise replace it.

Can I reuse the old pressure plate?

Only if you inspect it closely and it passes a spring‑tension test. Over‑time the springs lose elasticity and the plate may distort. A cheap replacement plate ensures even pressure and prevents uneven wear on the new disc.

What symptom points to a bad release bearing?

A high‑pitched whine that rises with engine speed, even when the clutch is fully engaged, is the classic sign. The noise usually disappears when you press the pedal because the bearing unloads.

How often should hydraulic fluid be changed?

Manufacturers typically recommend a flush every 30,000km or every 2‑3years, whichever comes first. Water contamination reduces the fluid’s boiling point, leading to spongy pedal feel.

Is a clutch alignment tool really necessary?

It’s cheap insurance. Without it, the disc can sit a fraction of a millimetre off‑centre, causing uneven wear and a noisy release. The tool costs under £20 and saves hours of troubleshooting later.