Suspension Noise Diagnostic Tool

Identify what might be causing your vehicle's suspension noise. Select the sound you're hearing and additional conditions to get a diagnosis.

Quick Summary

- Clunking, squeaking, or rattling usually points to specific suspension components.

- Shock absorbers and struts add "thud" or "popping" noises when they’re worn.

- Spring or bushing wear creates squeaks or creaks, especially over bumps.

- Control arms, ball joints, and CV joints produce clunks when they lose tightness.

- Run basic visual checks before booking a mechanic.

Ever heard a strange "clunk" every time you hit a pothole and wondered what’s going on under the car? That bad suspension sound is your vehicle’s way of telling you something isn’t right. In this guide we’ll break down the most common noises, link each one to the part that’s likely at fault, and give you a simple, step‑by‑step way to spot the problem before it turns into a costly repair.

Understanding Your Suspension System

Suspension system is the collection of parts that connects a vehicle’s wheels to its frame, handling shocks, maintaining tyre contact, and keeping the ride stable. Think of it as the body’s shock‑absorbing network. When any piece gets worn, it can make noise, change handling, or even cause safety issues.

Common Noises and What They Mean

Cars speak in sounds. Below is a quick sound‑to‑part cheat sheet:

- Clunk or bang - usually a loose joint or worn shock absorber.

- Squeak or squeal - often a dry bushing or failing spring.

- Rattling - could be a broken sway bar link or loose mount.

- Knocking - often a worn ball joint or CV joint under load.

- Thud or popping - typical of failing struts or worn spring insulators.

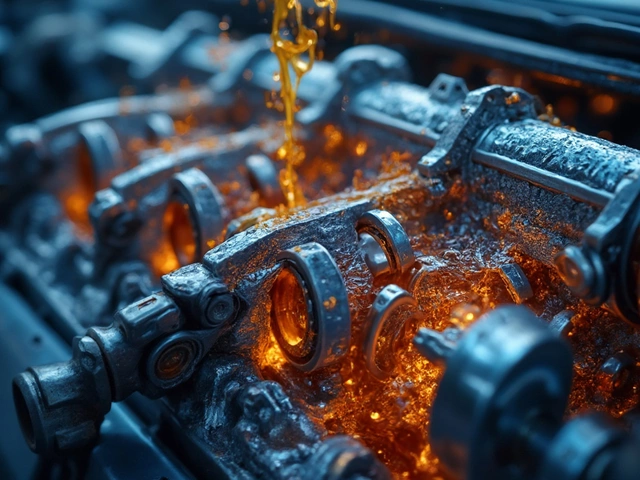

Shock Absorbers and Struts: The Noise Makers

Shock absorber is a hydraulic device that damps the motion of the suspension springs, converting kinetic energy into heat. When the oil inside leaks or the piston wears out, you’ll hear a deep thud or a soft pop each time the wheel moves up and down.

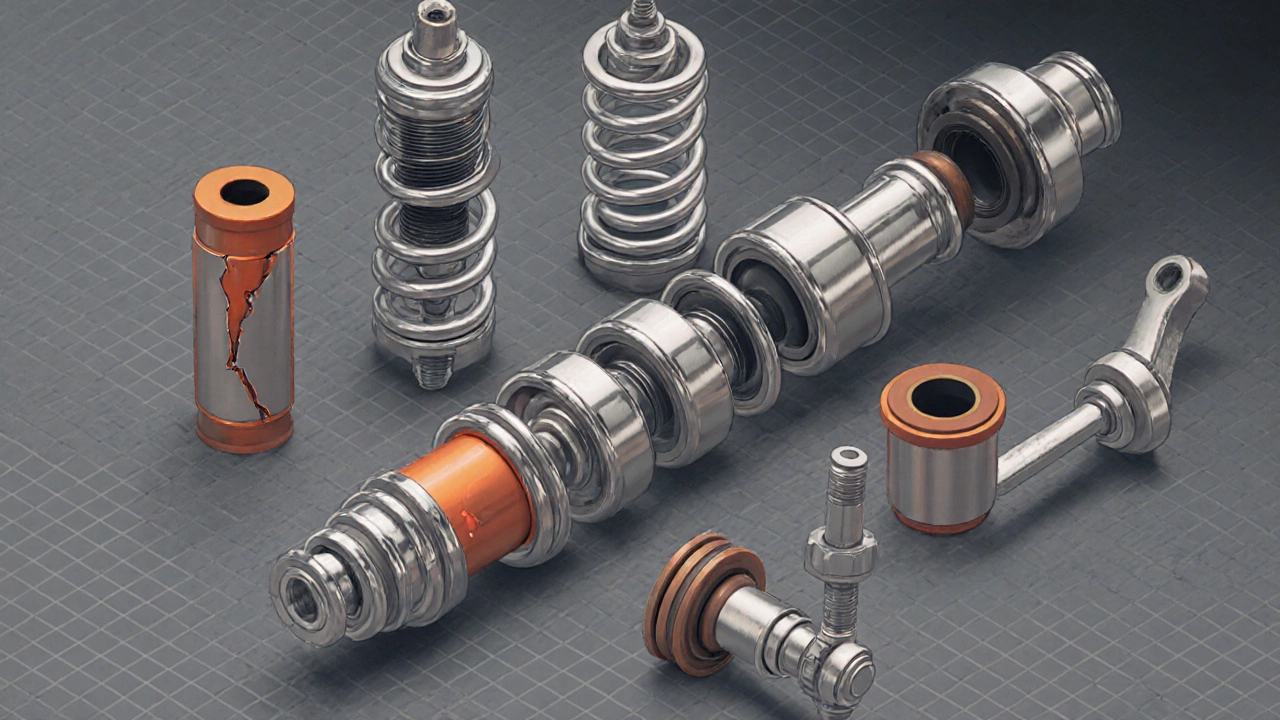

Strut is a structural component that combines a shock absorber with a coil spring, also supporting the vehicle’s weight. A failing strut often makes a sharp “snapping” sound, especially when you turn sharply. The difference? Struts are more visible because they attach to the wheel hub.

Springs and Bushings: The Silent Squeakers

Coil spring is a helical steel component that stores energy and helps keep the vehicle level. A cracked or sagging spring can cause a high‑pitched squeak as it flexes over bumps.

Bushing is a rubber or polyurethane cushion that isolates metal parts, reducing vibration and wear. When rubber dries out, the metal‑on‑metal contact creates a persistent squeak that gets louder with speed.

Control Arms, Ball Joints, and CV Joints: The Clunk Sources

Control arm is a hinged suspension link that connects the wheel hub to the chassis, allowing vertical movement. Loose bolts or worn bushings on a control arm will make a clunk every time you hit a curb.

Ball joint is a spherical bearing that enables steering and suspension movement. When the joint’s grease dries out, a knocking sound appears during turns.

CV joint is a constant‑velocity joint that transmits power to the wheels while allowing them to turn. A bad CV joint makes a rhythmic clicking or knocking that intensifies when accelerating.

Sway Bar and Links: The Rattlers

Sway bar is a tubular steel bar that reduces body roll during cornering. Worn sway bar links create a metallic rattling noise, especially on winding roads.

Diagnosing the Issue: A Simple Checklist

- Park on a flat surface and bounce each corner of the car. If a corner bounces more than two times, the shock absorber or strut is likely worn.

- Listen closely while the car is rolling at low speed. Pinpoint the side where the noise originates.

- Inspect visible components for oil leaks (shocks), cracked springs, or missing rubber (bushings).

- Grab the wheel at the 12 and 6 o’clock positions and shake it. Excess play indicates a bad ball joint or CV joint.

- Check all bolts on control arms and sway bar links; tighten if any are loose.

When to Call a Professional

If any of the following are true, it’s time to book a mechanic:

- The car pulls to one side after a bounce test.

- You feel vibration through the steering wheel at highway speeds.

- The noise is accompanied by a visible leak or a broken component.

- Safety feels compromised - especially with ball joints or CV joints.

Professional technicians have the tools to press‑fit ball joints, replace struts, and balance springs correctly. Skipping a repair can lead to uneven tyre wear, poorer handling, or even a loss of control.

Quick Reference Table

| Noise Type | Likely Component | Typical Conditions | Immediate Action |

|---|---|---|---|

| Clunk / bang | Control arm, ball joint, CV joint | Hitting bumps, turning sharply | Inspect joints, tighten bolts |

| Squeak / squeal | Bushing, spring, bushings on shock | Low‑speed cornering, continuous driving | Lubricate or replace rubber parts |

| Rattling | Sway bar link, mounting brackets | Fast cornering, uneven roads | Check and replace worn links |

| Thud / pop | Shock absorber, strut | Going over potholes, heavy loads | Test bounce, replace if excessive |

| Knocking | Ball joint, CV joint | Accelerating while turning | Professional inspection needed |

Frequently Asked Questions

What causes a clunking noise over bumps?

A clunk usually points to a worn control arm, loose ball joint, or a failing shock absorber. The impact forces move the loose part, creating the audible knock.

Why does my car squeak when I turn the wheel?

Squeaking on turn‑in is often caused by dry rubber bushings or a worn tie‑rod bushing. The friction between metal and hardened rubber produces a high‑pitched squeal.

Can I replace a bad shock absorber myself?

If you have basic hand tools and a jack, you can replace a shock on many front‑wheel‑drive cars. However, proper torque specs and safety precautions are essential. For struts, a professional press may be required.

What does a rattling noise from the rear indicate?

Rear rattles often stem from a loose sway bar link, worn rear shock mounting, or a broken rear spring. Visual inspection of those components usually reveals the culprit.

How often should suspension components be inspected?

A thorough suspension check every 12,000 miles (or annually) is a good rule. After hitting a major pothole or experiencing a crash, inspect immediately.